- response@insulationjackets.net

- Indira Nagar, Chinchwad, Pune - 411033, Maharashtra, India.

Applications

Heaton Engineering Pvt. Ltd. offers high-performance insulation jackets designed to serve a wide range of industrial applications where thermal efficiency, operational safety, and maintenance accessibility are critical.

Our insulation jackets are custom-engineered to suit various types of equipment, playing a key role in reducing heat loss, protecting personnel from hot surfaces, and enhancing overall energy efficiency. They are commonly used in:

Valves and Flanges

Prevents heat loss in piping systems and maintains fluid temperature.

Pumps and Compressors

Maintains fluid viscosity and helps reduce energy consumption.

Textile Machinery

Ensures consistent process heat for spinning and processing applications.

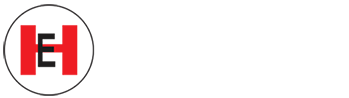

Ship Engine Systems

Ideal for insulating fuel lines, filters, and exhaust parts in confined marine environments

Engine Exhausts

Controls surface temperatures and improves energy containment.

Steam Manifolds

Enhances the performance of steam distribution systems by retaining heat.

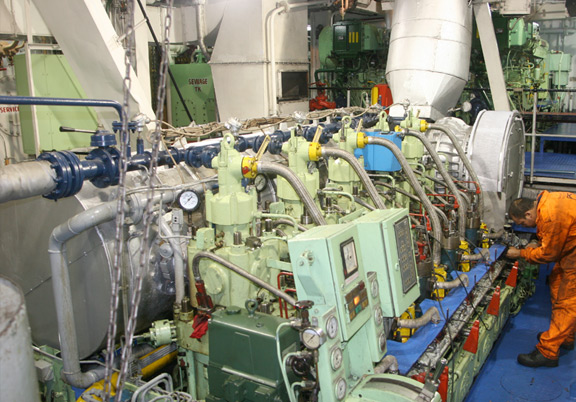

Heat Exchangers and Boilers

Improves insulation and safety while allowing easy removal during maintenance.

Steam and Gas Turbines

Provides thermal stability and safety in high-temperature zones.

Chemical Processing Equipment

Offers protection and temperature control for pipes, vessels, and sensitive instruments in chemical plants.

Niche & Specialized Applications

In addition to standard industrial uses, Heaton’s insulation jackets are also engineered for specific, high-demand scenarios where safety and heat management are critical:

Insulation Jacket for Ship

Engine Filters

Shields hot filter surfaces in engine rooms, preventing accidental burns in tight working spaces.

Insulation Jacket for Fuel Lines

– Ship Engine

Maintains optimal fuel temperature in marine applications for improved flow and safety.

Insulation Jacket for Spin Beams

– Textile Industry

Maintains thermal consistency in fiber production, ensuring quality and efficiency.